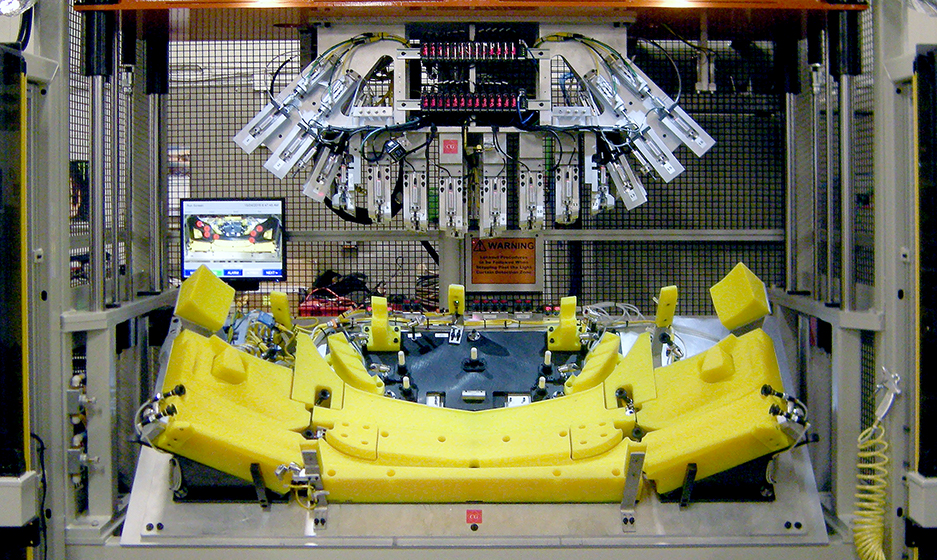

End Of Arm Tooling (EOAT)

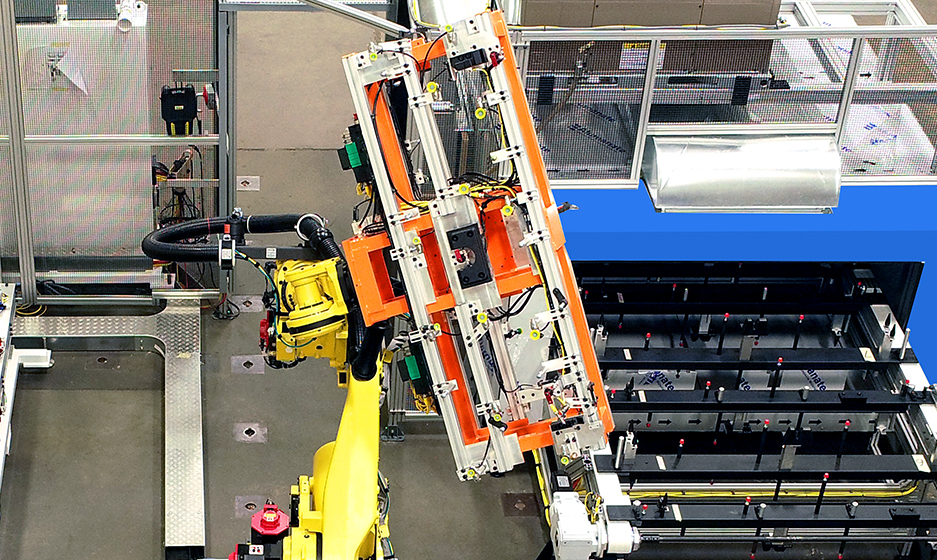

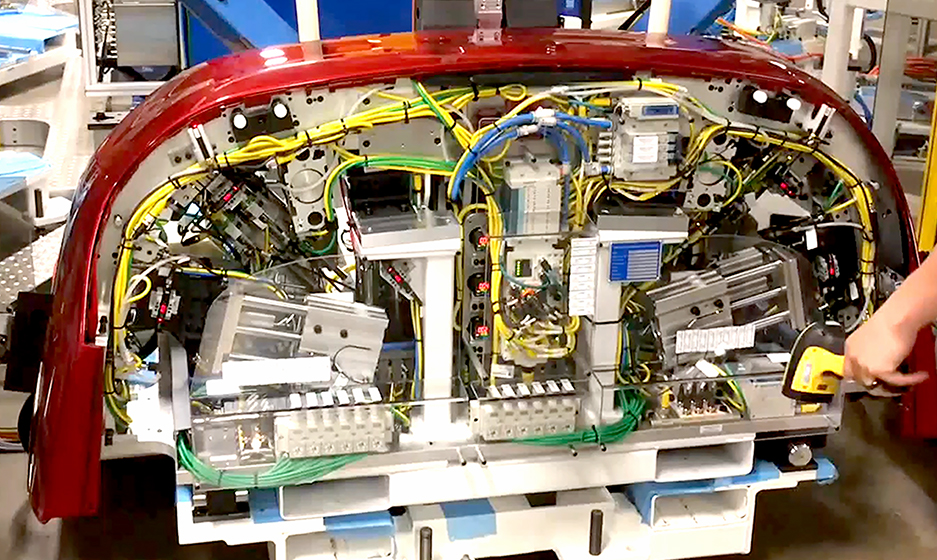

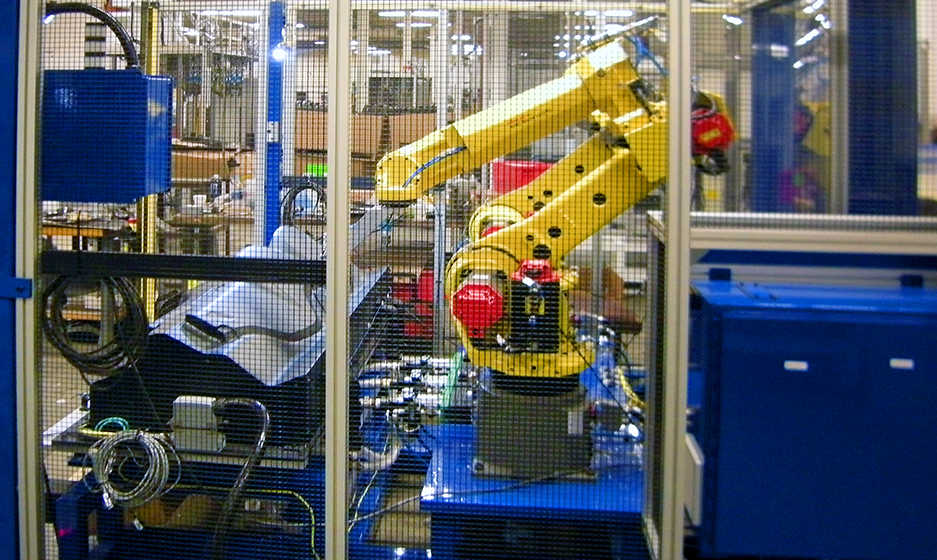

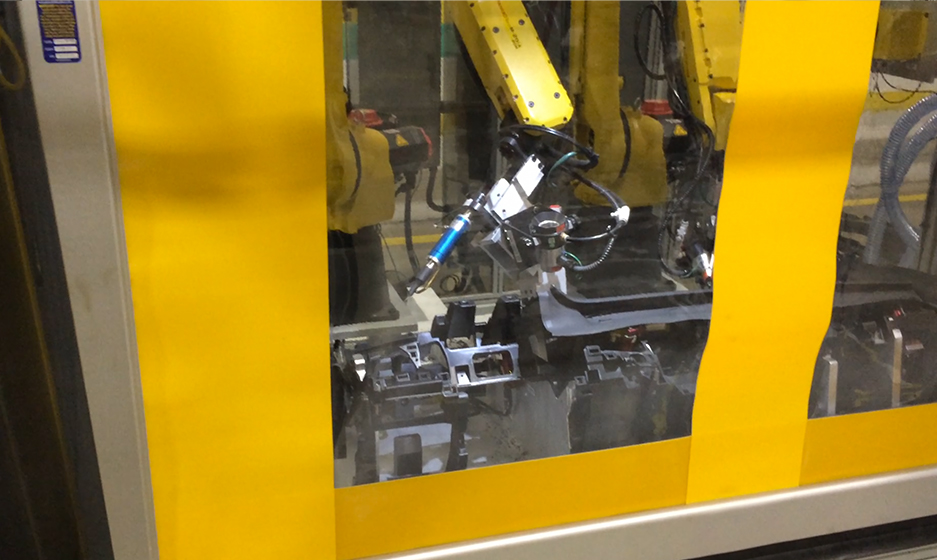

Totally Automated Systems brings a high level of expertise in the design and manufacturing of End Of Arm Tooling (EOAT) for customers in the Automotive Industry. These end effectors or devices that attach to the end of a robotic arm are beneficial in giving a robot specific functionality and can be easily changed out for different application needs. In addition, they can be assembled or built to handle many processes at the same time.

- Complete In-House Design & Engineering

- Full Simulation Studies

- Mechanical & Vacuum Retention Systems

- Interchangeable

- ATI & Custom Integrated Quick Disconnect Systems

- Racks & Stands for Interchangeable Tooling

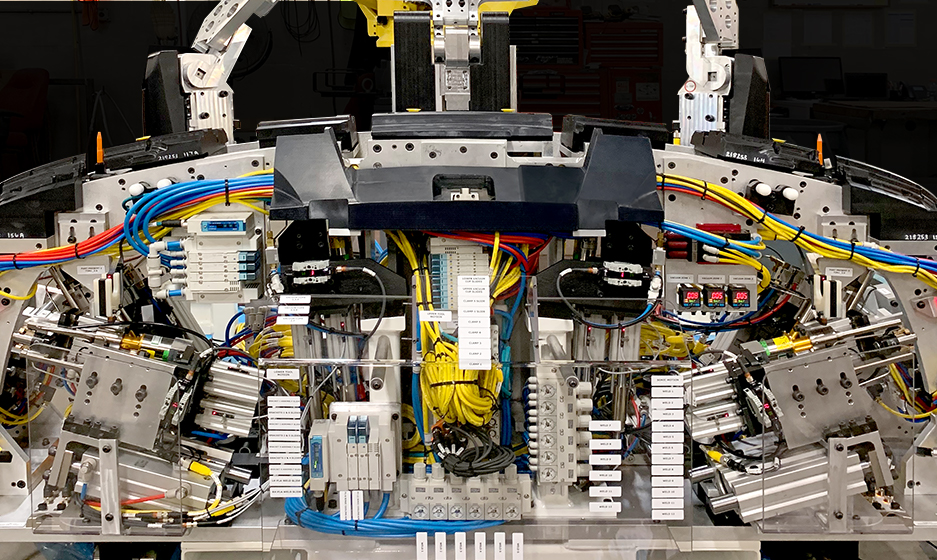

- TA Systems Next Gen Dual EOAT was Developed On Proven Technology – Over 3 Million Cycles:

- Best Robotic Part Quality On The Market

- High Reliability

- Less Robots – Less Capital Investment

- Less Stations Required – Less Plant Floorspace

- Machine Simplicity

- Better Weld Quality

- Easier System Support

- Simplified Programing

- Reduced Maintenance of The Robotic System

- Faster Launch

- Reliability

- Simplified Mechanics

- Improved Cabling & Dress Pack

- Crash Protection

- Simplification For Plant Maintenance

- Simplified Programming (100% Robot Pathing)

- Simplified PLC Programming

- All Replacement Parts Easily Accessible

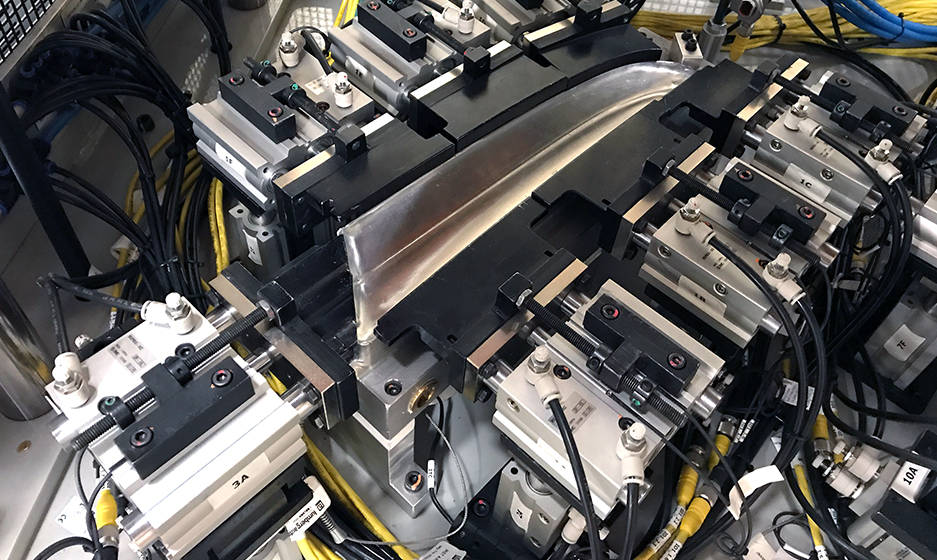

- Improved Mechanics

- Shorter Stronger Stack

- Smaller Foot Print

- Smaller Lighter & Stronger Tool

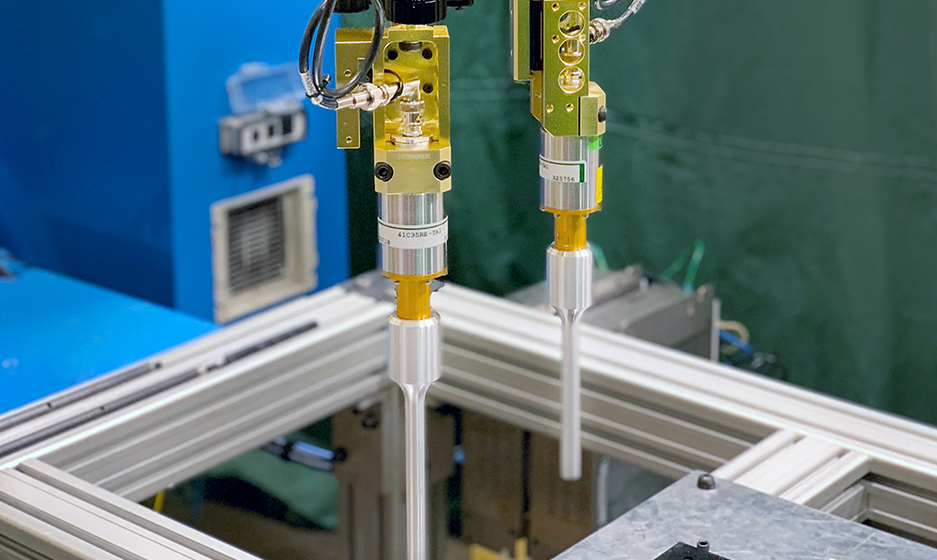

- Larger Dual Point Span (50mm -250mm)

- Longer Stroke (80+mm)

- Improved Sonics

- TA Sonics 2.0

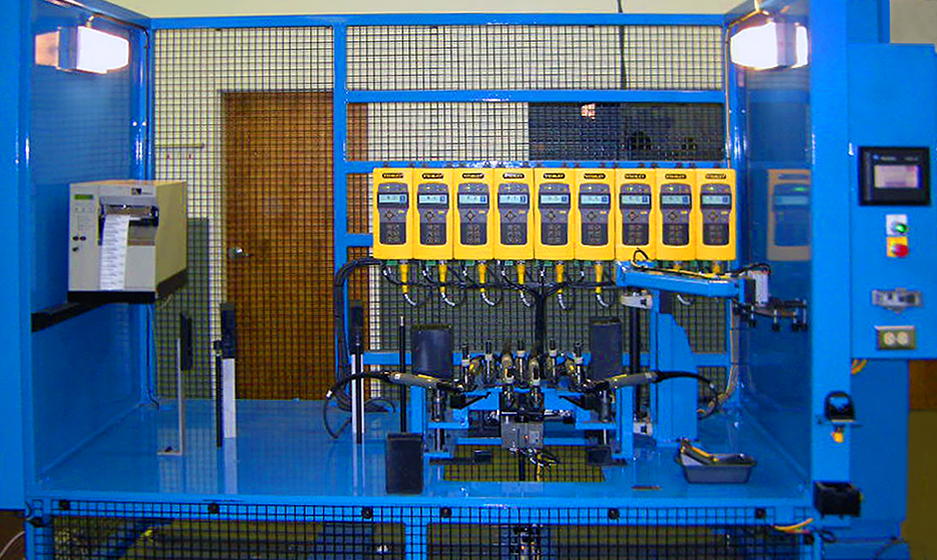

- Pneumatic Sonic with Absolute Encoder

- Weld By Distance, Energy, Peak Power, Other

- Graphical Interface of Weld Performance

- 4 Sec Point To Point For Standard Boss (2 Welds)

- Dedicated Equipment

- Robotic Dedicated Equipment